All categories

1 / 4

Details

Price TypeNegotiable

ConditionNew

Description

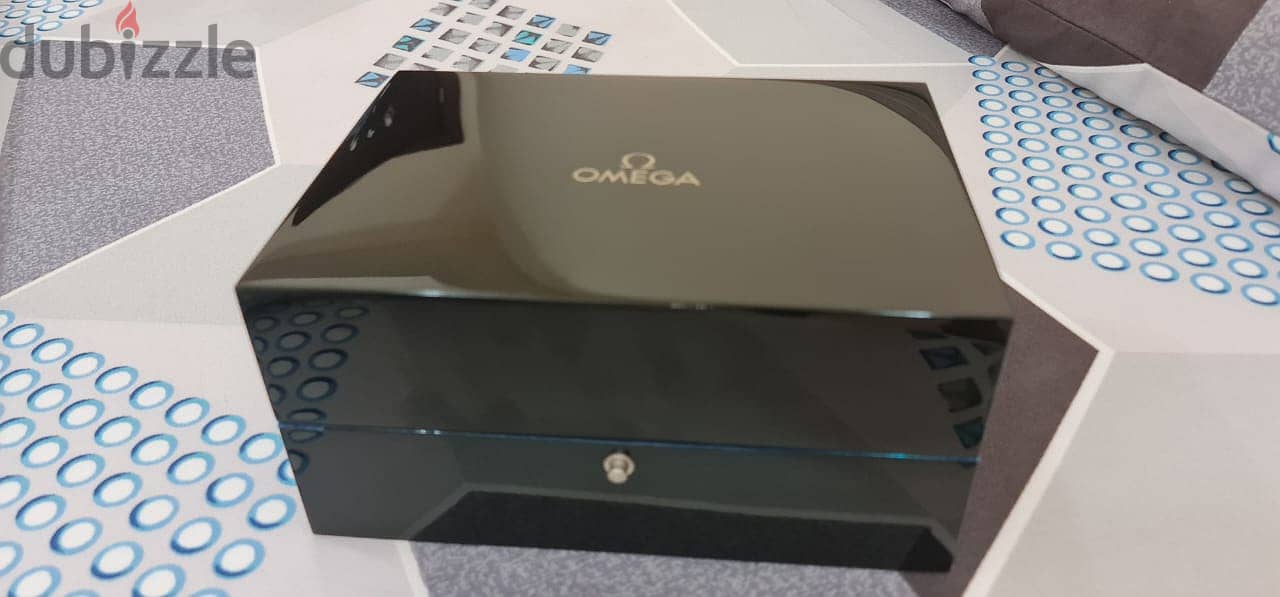

Omega Dark side of the moon-Speedmaster Dark Side of the Moon-Grade 5 Titanium

Titanium alloys are light, corrosion-resistant, biochemically inert and able to withstand extreme temperatures. These properties make them particularly appropriate for products in the aircraft, spacecraft and medical sectors. They achieve the perfect balance between solidity, corrosion-resistance and workability. Grade 5 titanium offers a bright grey colour that is close to that of stainless steel, and suits both "brushed" and "polished" finishing.

Ceramic

OMEGA has unrivalled expertise in the use of ceramics, dating back more than 10 years. Taking its origin from the Greek word "keramos", ceramic is an inorganic, non-metallic substance obtained by firing at high temperatures. It allows the creation of completely dense watch parts with exceptional mechanical properties. Ceramic is one of the most popular choices for customers when selecting their timepiece, thanks to its appealing colour range and specific properties, such as it being two times lighter than stainless steel, hardwearing, highly scratch-resistant, chemically inert, hypoallergenic, and non-magnetic.

Sapphire Crystal

To really appreciate the finer details of a timepiece, OMEGA uses synthetic sapphire crystal with a highly scratch-resistant and anti-reflective treatment. Before the machining and finishing processes take place, the sapphire crystals are produced under the Verneuil process, also called flame fusion. It involves the melting of the raw substance using oxyhydrogen flame and the crystallisation of the melted droplets to form a cylinder. Graded 9 on the Mohs-hardness scale (graded 1-10), the resulting sapphire crystals are virtually scratch-proof and very hard, ensuring an unhindered vision at all times.

Location

Kuwait

Ad id 102546284

Report this ad

Listed by private user

Varun Kamal

Member since Sept 2024

See profile

Your safety matters to us!

- Only meet in public / crowded places.

- Never go alone to meet a buyer / seller, always take someone with you.

- Check and inspect the product properly before purchasing it.

- Never pay anything in advance or transfer money before inspecting the product.